Battery Industrial Shredders

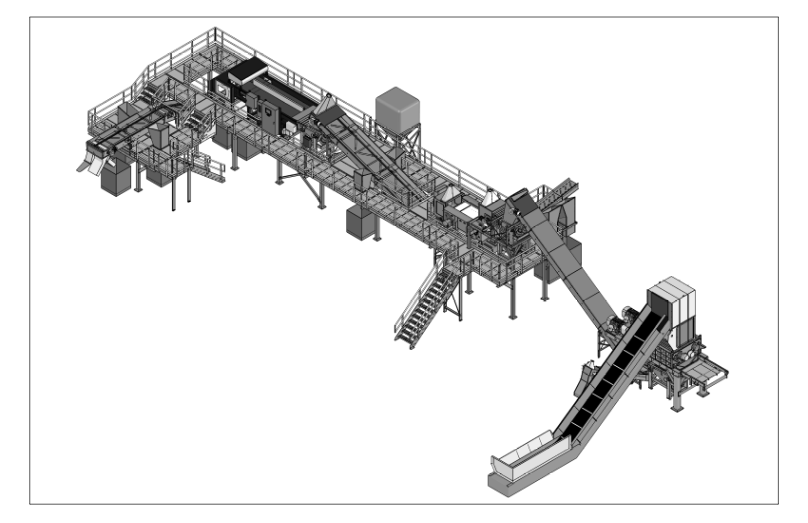

Battery Industrial Shredders employ a primary Industrial shredder, either a dual shaft or quad shaft Industrial shredder, characterized by low-speed, high torque, as the initial stage of Industrial shredding prior to subsequent processing.

Within Li-ion batteries and others, valuable elements such as cobalt, nickel, copper, and assorted precious metals are present, capable of being recycled and repurposed after effective separation. To mitigate fire hazards, Battery Industrial Shredders integrate a continuous water bath and a supplementary chemical-based fire suppression solution.

Preceding recycling, the majority of batteries require discharge. Augmenting Battery Industrial Shredders with conveyors, screens, separation apparatus, and washing stations can be advantageous. The overall approach often encompasses preliminary treatment and direct recovery of electrode materials through physical procedures.

Tailored to individual needs, Battery Industrial Shredders and their Industrial shredding systems are meticulously crafted to address various applications, spanning the recycling of electric-vehicle batteries, lithium-ion batteries, absolyte batteries, alkaline batteries, and lead-acid batteries, among others.